|

ECOTRAN PPS(Polyphenylene Sulfide) |

|||||

|

Tecnical - PPS특성 |

|||||

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ECOTRAN PPS- 특성 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ECOTRAN PPS 특성 - Low Haze |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

주요 특징 : 내열성, 기계적 성질, 냉각수 저항성, 낮은 헤이즈, 치수 안정성, 절연성, 전기적 특성, 내약품성, 열전도율 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

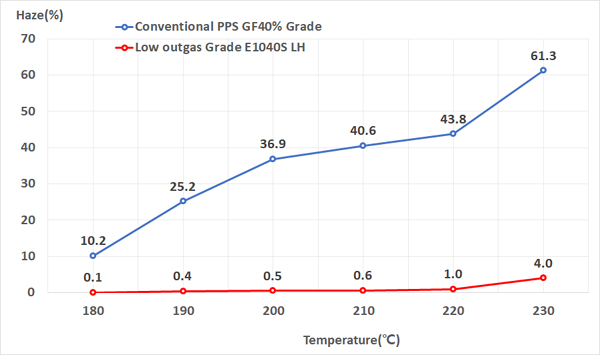

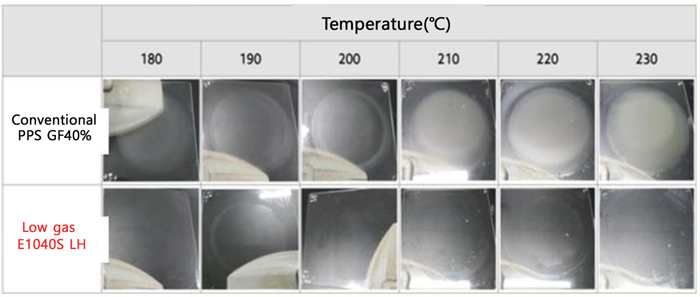

헤드램프 헤이즈는 플라스틱이 고온에 노출되면 가스를 생성하기 때문에 필연적으로 발생합니다. 근본적인 문제를 해결할 수 있는 다른 솔루션이 나오지 않았기 때문에 많은 글로벌 자동차 부품 엔지니어들이 헤드램프 내부 구조 설계에 집중하여 문제를 해결해 왔지만, 현대모비스는 HDC폴리올 ECOTRAN PPS 수지를 사용하여 헤드 램프 헤이즈 문제를 해결했습니다. ECOTRAN PPS는 무염소 공정으로 생산되며 잔류 용매를 포함하지 않습니다. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| *HDC Polyall Lab data. 조건에 따라 결과치는 변경될 수있음 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

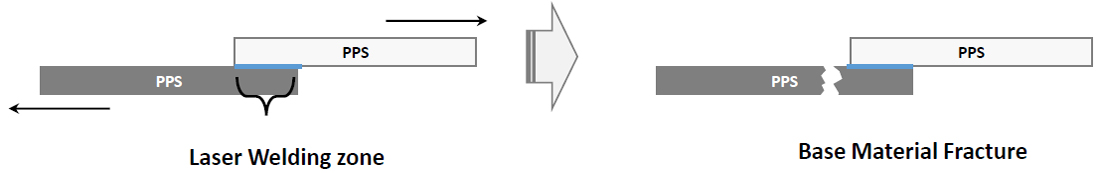

ECOTRAN PPS 특성 - Laser welding |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ECOTRAN PPS, E1040HRW : Laser Weldable Compound Grade |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ECOTRAN PPS E1040HRW : 고객평가 결과 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ECOTRAN PPS 특성 - 내화학성 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

본사 : 경남 양산시 물금읍 증산역로 135, 504호 (퍼스트조양) 이엔지폴리머주식회사 / 이메일

: engp@engpolymer.co.kr / 055-383-9510, FAX : 055-383-9516 본사약도▶ |